Features of WS Dry Lube and Their Use

Features of WS Dry Lube

The use of WS dry lube is bound to enhance the profitability of an entity in the longer run. Hence it is referred to as tungsten disulfide and it is available in a solid or a dry lubricant form. Such a powder goes on to provide an unmatched substance, as it can be Molybdenum or graphite. Otherwise, it goes by the name of MOS2. For high-pressure or high-temperature applications also it may be put to use. At around a specific temperature range it is expected to provide a particular form of temperature resistance. This is something that may occur in a normal ambiance that occurs in the form of a vacuum.

Features of WS2 Dry Lube and their proper use are important

The features of WS dry lube hold a lot of relevance. There may arise a situation where you may go on to use this form of a coated film, and a few pointers that may be high to the tune of 300,000 PSI. One has the form of WS2 dry lube and it can be an alternate to MOS2. If you go on to witness the comparison chart an obvious thing that could spring up is that there are some more things to accomplish. Such a form of solution is expected to provide the lowest coefficient of fiction. The use of this application happens to be limitless, and with the conceivable notion, a lot of things can be tried.

It is possible to be using the solution and then mix the wet lubricants with grease, oil, or synthetic lubricants. You can mix the powder with oil as this goes a long way in enhancing the lubricant feature of this mixture. It goes on to incorporate a new degree of pressure with the traits along with properties coming to the fore. When you are using WS2 it would enable things to be coated or the movement of the parts. One thing is for sure their role in the reduction of friction is paramount.

WS2 and the qualities on offer

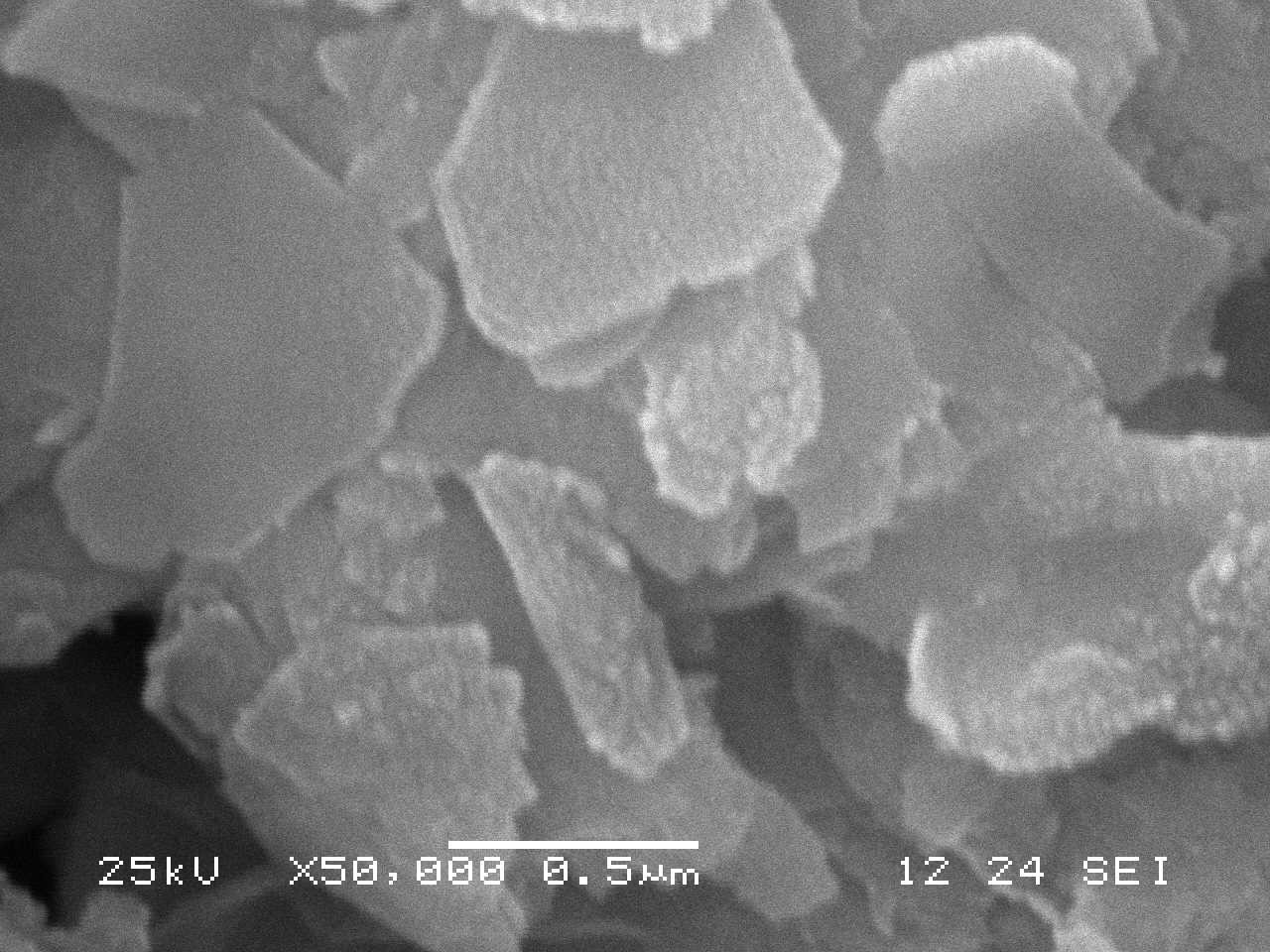

When you are using WS2 it goes on to enhance the lubrication feature with the load carrying capacity for a prolonged period of time. It goes a long way to help in spraying the substrate where you do have the role of the cool and dry pneumatic air. There is no need for any form of binders and this is something that could take place at a normal room temperature. There is the coated film and it is 0.5 microns thick. Do pay attention to the alternative process of application and you can obtain the powder by mixing the components, with the necessary products.

Comments

Post a Comment